Modern Tool Room Products

COINDIA Modern Tool Room offers a wide range of services especially to small scale industries.

A solution for all your engineering needs, offers you services on any variety of Tooling, Mass production on CNC Turning and 5Axis CNC Milling besides Rapid prototyping.

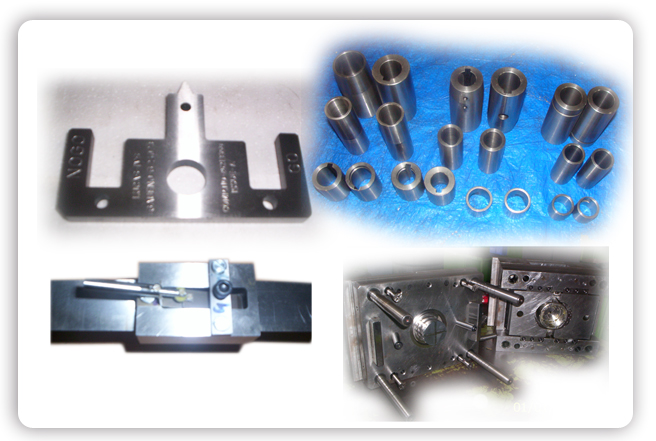

COINDIA’s Product Die and Mould Centre (PDMC), part of Common Modern Tool Room (CMTR) has established extensive manufacturing capabilities covering areas of Product Development, Press Tools, Plastic Moulds, and Pressure Die Casting Dies, backed by Pro-E, UG, AutoCAD software and hardware. Riding on this strong base, COINDIA will endeavor to make high end Tools & dies for all spheres of Industries starting from serving MSMEs down to top end high precision jobs like Aero space.

Charges /Price

With win-win pricing policy COINDIA shall offer shortest lead time to address effective customer satisfaction, to make Coimbatore based Industries enjoy edge in the globally competitive market.

Product Development

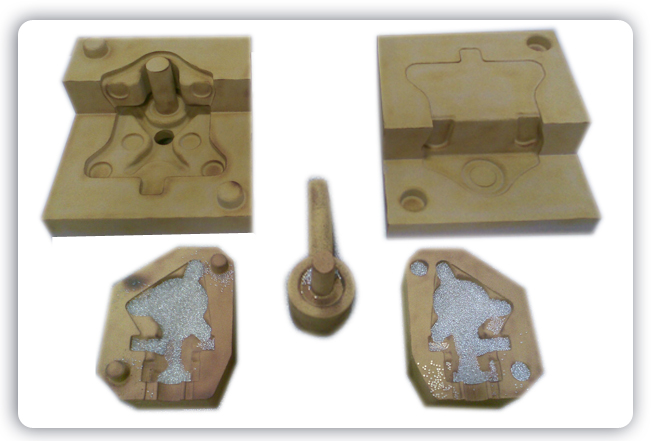

The said Centre enables Product development through reverse engineering with supporting Rapid Prototyping of plastic and metal components (patterns and core for foundry) from solid models; cutting short development time considerably and without Dies or Moulds. Software domain of PDMC handles solid modeling and 2D Drafting. The Design studio of PDMC is equipped with Pro Engineers and Unigraphics software on fastest work stations, ably supported by Mould Flow and Solid cast software.

Contemporary business process like Concurrent Engineering and Continuous process improvement practices reduces tooling Manufacture duration substantially. High precision gadgets and Measuring instruments, disciplined process controls with NIL rework/ rejection, eliminating time wastages. Components production wing of PDMC takes care of pressed and CNC turned parts.

This One stop Centre can handle you from Concept to Commissioning of your Die and Moulds needs. PDMC has already executed few intricate plastic moulds including a hot runner mould, machines large number of parts in the various imported brand new machineries.

PDMC believe in participative approach and look forward to all your needs.

A well equipped Design centre with the advanced soft wares like Unigraphics, ProE and a machine shop with all varieties of advanced machines from Worldwide leading manufactures such as DECKEL MAHO 5 axis machine, AGIE CHARMILLES & MITSUBHISHI Wire cut machines, MOORE Jig boring machine etc enables us in handling of any type of tooling, say Press tools, Injection Moulds, Die Casting Dies etc. in competent timings.

Supported by Quality assurance department with Co ordinate measuring machine, profile projector etc. in doing inspection of any complicated profiles also ensures the quality. Our manufacturing activities are steered by a team of experienced professionals.

A cluster of CNC turning machines of multi combination of horizontal and vertical, smaller and bigger, which runs 24 hours/365 days and 5 axis CNC mill supported by line inspectors available for handling mass productions.

A rapid prototype machine, first of its kind in South India,( second in India) from the world wide leader EOS keeps us unique in supporting new engineering activities all over and especially for Foundry units. Adding Scanning system from RHENISHAW helps us keep us as a solution for all needs modeling stage of a product.

Machines - CNC MILLING

1) MACHINING CENTRE : DMG, 4 AXIS MODEL : DMC 64V LINEAR COUNTRY : GERMANY

Specification

| XYZ Travel | 640*600*500 |

|---|---|

| Clamping Area | 850*600 |

| Spindle Speed | 12000 rpm |

| Tool Magazine | 30 Tools |

| Max. Tool Dia/Weight | 100/7 kg |

| Positioning accuracy XYZ | 8*20*20 micron |

| Tool Taper | SK 40 |

| Machine Controller | Heiden Hain TNC 530 |

CNC MILLING

2) MACHINING CENTRE : DMG, 5 AXIS MODEL : DMU 60 MONO BLOCK COUNTRY : GERMANY

Specification

| XYZ Travel | 630*560*560 |

|---|---|

| Clamping Area | 600mm |

| Spindle Speed | 12000 rpm |

| Tool Magazine | 24 Tools |

| Positioning accuracy XYZ | 1*1*10 micron |

| Max. Wt on Table | 900 kg |

| Table Rotating Speed C axis | 40rpm |

| Machine Controller | Heiden Hain TNC 530 |

| Rotating Axis B Axis | 120° |

CNC MILLING

3) MACHINING CENTRE : LMW MODEL : L MILL 55 COUNTRY : GERMANY

Specification

| XYZ Travel | 575*410*460 |

|---|---|

| Spindle Speed | 6000mm |

| Tool Taper | BT 40 |

| Tool Magazine | 20 Tools |

| Machine Controller | Fanuc | Positioning accuracy XYZ | 10 microns |

| Repetabiligy | 3 microns |

CNC MILLING

4) MACHINING CENTRE : HASS MODEL : TMI COUNTRY : USA

Specification

| XYZ Travel | 762*305*406 |

|---|---|

| Spindle Speed | 4000 rpm |

| Tool Taper | BT 40 |

| Max. Wt on Table | 450 kg |

| Machine Controller | HAAS | Positioning accuracy XYZ | 10 microns |

| Repetabiligy | 5 microns |

CNC MILLING

5) WIRE EDM : AGIE CHARMILLES MODEL : ROBOFILL 240 SL COUNTRY : SWISS

Specification

| XYZ Travel | 350*220*220 |

|---|---|

| Max. Wt on Table | 750 kg |

| Max. Cutting Speed | 300 mm2/min |

| U.V Travel | 350*220 |

| Max Taper | 30° on 200mm Ht | Minimum finish | 0.22ŵ |

| Wire Dia & Spool Wt. | 0.25 mm/4 kg |

CNC MILLING

6)CNC SPARK EDM : ARD MODEL : M 50 CA COUNTRY : KOREA

Specification

| XYZ Travel | 350*250*300 |

|---|---|

| Max. Wt on Table | 500 kg |

| Generator Current | 45 Amps |

| Max. Electrode Wt | 50 kg |

| Magnetic Table, Magnetic Flushing set fitted. 3R Cluck, 3R Tool Holders, 3R C axis |

CNC MILLING

7) MANUAL EDM : ELECTRONICA MODEL : ELECTRA EMS 5535 PS ZNC COUNTRY : INDIA

Specification

| XYZ Travel | 350*200*250 |

|---|---|

| Generator Current | 45 Amps |

| Best Surface finish | 0.3µ RA |

| Max. MRR (cu-st) | 350 mm3 /min |

CNC MILLING

8) TURNING CENTRE : HWA CHEON MODEL : VT350 (Vertical) COUNTRY : KOREA

Specification

| Max. Turning Dia/Length | 350*350 |

|---|---|

| Spindle Speed | 30 to 2500 rpm |

| Feed X/Z | 420/350 |

| No of Tools | 6 |

CNC MILLING

9) TURNING CENTRE : LMW (Horizontal 2m/c) MODEL : LL 20 TL5 COUNTRY : GERMANY

Specification

| Max. Turning Dia/Length | 320*500 |

|---|---|

| Spindle Speed | 40 to 3500 rpm |

| Positioning Accuracy X/z | 5/10 micron |

| Repeatability X/Z | 2/3 Micron |

CNC MILLING

10) TURNING CENTRE : DOOSAN VERTICAL MODEL : PUMA V550 COUNTRY : USA

Specification

| Max. Machining Dia | 730 mm |

|---|---|

| Max. Work Length | 730 mm |

| X axis | 390 mm |

| Z axis | 780 |

| Spindle Speed Range | 20-2000 rpm |

| Spindle Bore dia | 90 mm |

| No. of Tool Stations | 8 stations |

| OD Tool Height | 32 mm |

| Rapid Traverse | X12,000mm/Z16,000 mm |